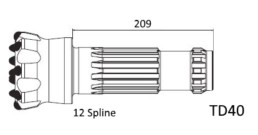

BIT SHANK – ATLAS COPCO COP44GE – EPIROC TD40

Download Catalogue

Drilling Applications

Geothermal Drilling

Waterwell Drilling

Blasting Holes / Quarry Drilling

Exploration and Construction Drilling

Advantages and Innovations

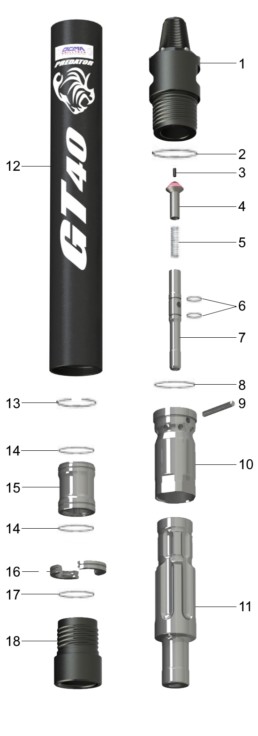

Dth Bit and Chuck

Bit shank with 12 Spline and Hard Faced Chuck to optimize the Wear Resistance. The GT Series are designed to eliminates the blow tube/foot valve from the drill bit „Tubeless Technology“.

Cylinder

Hardened and Heavy Duty Wear Sleeve for optimum resistance in abrasive conditions and increase the Hammer life.

Piston

The robust no ported Piston design increases Impact Energy on Drill Bit and improves Drilling Performance.

Choke System

The GT Series DTH Hammers are equipped with Choke System that allows the driller to adjust the volume of air through the hammer to optimize cutting evacuation and drill under a column of water.

Air Flow Chamber

The Innovative Air Flow Chamber optimize the air expansion and compression, by minimizing turbulence and reaching great Piston blow frequency, more penetration rate than 25/30 % with lower Air consumption that means lower fuel costs per drilling meters.

Advantages and Innovations

Dth Bit and Chuck

Bit shank with 12 Spline and Hard Faced Chuck to optimize the Wear Resistance. The GT Series are designed to eliminates the blow tube/foot valve from the drill bit „Tubeless Technology“.

Cylinder

Hardened and Heavy Duty Wear Sleeve for optimum resistance in abrasive conditions and increase the Hammer life.

Piston

The robust no ported Piston design increases Impact Energy on Drill Bit and improves Drilling Performance.

Choke System

The GT Series DTH Hammers are equipped with Choke System that allows the driller to adjust the volume of air through the hammer to optimize cutting evacuation and drill under a column of water.

Air Flow Chamber

The Innovative Air Flow Chamber optimize the air expansion and compression, by minimizing turbulence and reaching great Piston blow frequency, more penetration rate than 25/30 % with lower Air consumption that means lower fuel costs per drilling meters.

Advantages and Innovations

Dth Bit and Chuck

Bit shank with 12 Spline and Hard Faced Chuck to optimize the Wear Resistance. The GT Series are designed to eliminates the blow tube/foot valve from the drill bit „Tubeless Technology“.

Cylinder

Hardened and Heavy Duty Wear Sleeve for optimum resistance in abrasive conditions and increase the Hammer life.

Piston

The robust no ported Piston design increases Impact Energy on Drill Bit and improves Drilling Performance.

Choke System

The GT Series DTH Hammers are equipped with Choke System that allows the driller to adjust the volume of air through the hammer to optimize cutting evacuation and drill under a column of water.

Air Flow Chamber

The Innovative Air Flow Chamber optimize the air expansion and compression, by minimizing turbulence and reaching great Piston blow frequency, more penetration rate than 25/30 % with lower Air consumption that means lower fuel costs per drilling meters.

Advantages and Innovations

Dth Bit and Chuck

Bit shank with 12 Spline and Hard Faced Chuck to optimize the Wear Resistance. The GT Series are designed to eliminates the blow tube/foot valve from the drill bit „Tubeless Technology“.

Cylinder

Hardened and Heavy Duty Wear Sleeve for optimum resistance in abrasive conditions and increase the Hammer life.

Piston

The robust no ported Piston design increases Impact Energy on Drill Bit and improves Drilling Performance.

Choke System

The GT Series DTH Hammers are equipped with Choke System that allows the driller to adjust the volume of air through the hammer to optimize cutting evacuation and drill under a column of water.

Air Flow Chamber

The Innovative Air Flow Chamber optimize the air expansion and compression, by minimizing turbulence and reaching great Piston blow frequency, more penetration rate than 25/30 % with lower Air consumption that means lower fuel costs per drilling meters.